THz Materials

| Download THz Materials Datasheet (PDF, 2417 KB) |

Terahertz (THz) radiation occupies frequency range ~0.1-10 THz (~3 mm to 30 μm, 3 cm-1 to 300 cm-1) between microwave and far infrared spectral regions.

Unlike visible and infrared light, THz radiation can penetrate certain organic materials such as skin, plastics, textile and paper. Due to low photon energy, it doesn’t cause damage associated with ionizing radiation (e. g. X-rays). THz radiation cannot penetrate metals. These features of the radiation can be utilized for in-situ production monitoring (for example, in pharmaceutics), product quality control and THz imaging. It is also of great interest for other applications such as security control, packaging inspection, semiconductor characterization, chemical composition analysis and biochemical studies.

Traditional material for THz applications is the High Resistivity Float Zone Silicon (HRFZ-Si) as it is the most studied substance that is transparent in this range. Alongside this material, we have studied others that we considered promising for THz applications.

Below you can see transmission spectra and other characteristics of materials we use for THz optics production. Measurements in far IR and millimeter regions were made with FT spectrometers ABB Bomem DA3 and Bruker IFS 125HR (measure of inaccuracy is 2-3% below 100 µm and 4-5% over 100 µm). Measurements in visible and near infrared range were made using Perkin Elmer “Lambda-9” spectrophotometer (measure of inaccuracy < 0.5%).

1. Crystals

Crystals such as silicon, crystal quartz, and sapphire play an important role for THz applications.

1.1 High Resistivity Float Zone Silicon (HRFZ-Si)

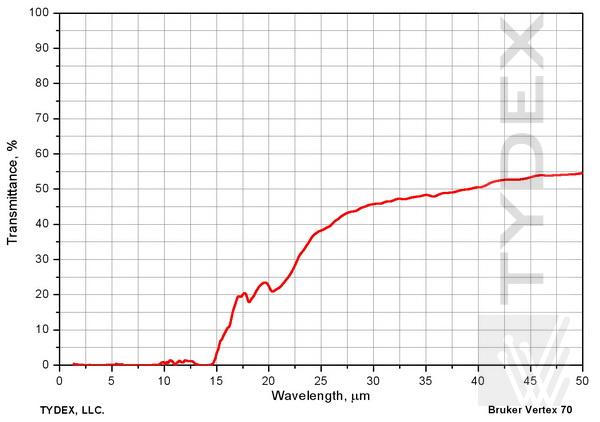

Besides synthetic diamond, high resistivity silicon is the only isotropic crystalline material suitable for the extremely wide wavelength range, from NIR (1.2 µm) to millimeter (1000 µm) and more. Compared to diamond, it is much cheaper to grow and machine. Moreover, it may be produced in considerably larger dimensions, allowing production of wider variety of optical parts. Silicon is one of the most workable materials suitable for manufacture of components for the fast evolving field of terahertz photonics.

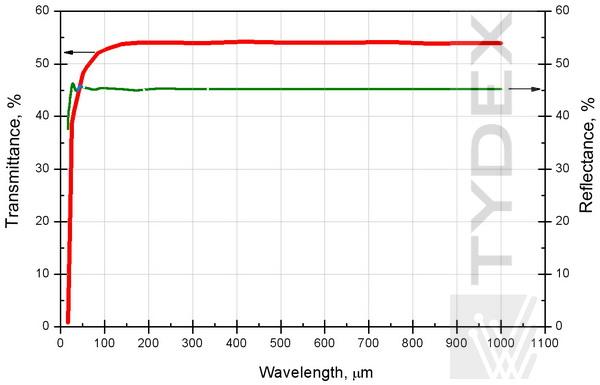

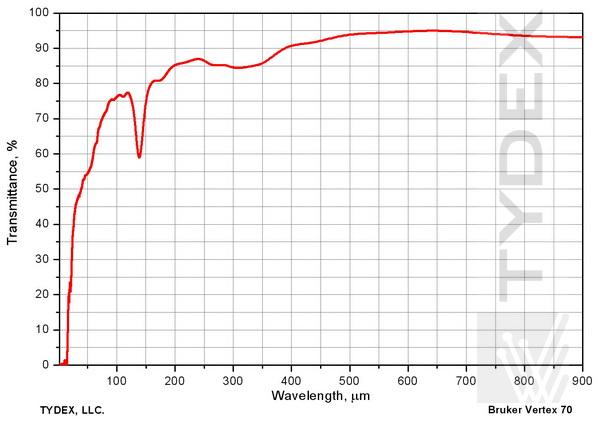

For THz components we use High Resistivity Float Zone Silicon maintaining 50-54% transmission between 50 and 1000 µm (and for longer wavelengths up to 8000 microns).

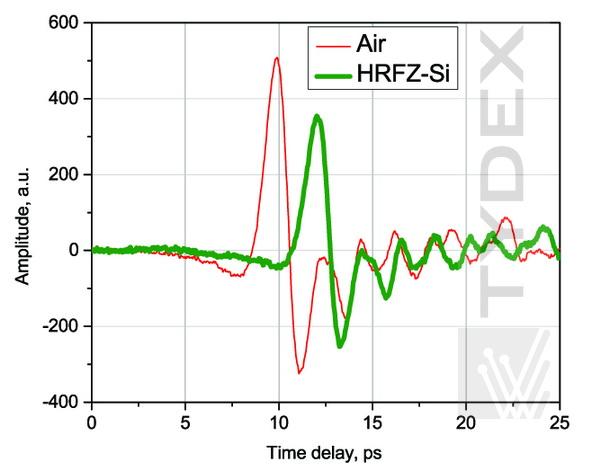

HRFZ-Si has low losses in THz range. Fig. 2 shows that the waveform of a THz signal passing through air is identical to the waveform of signal passing through high-resistivity silicon. It indicates the lack of absorption in silicon.

Fig. 1. Transmittance and reflectance of high-resistivity silicon. THz range.

Fig. 2. THz signals passing through air and high-resistivity silicon (*).

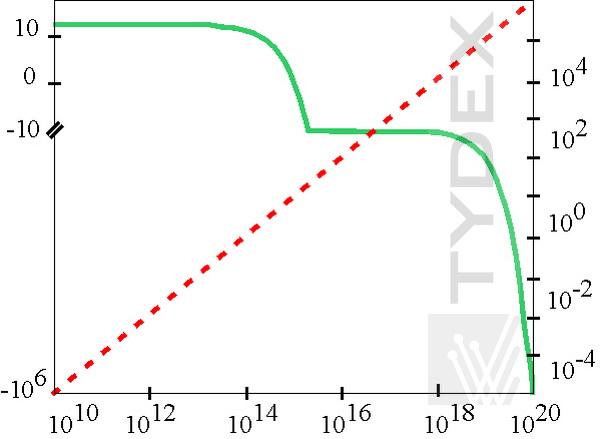

The complex dielectric permittivity of silicon depends on its conductivity, i.e. free carrier concentration. Figure 3 shows the dielectric permittivity of silicon at 1 THz vs impurity content. For low impurity concentration the dielectric permittivity has a real value, and is equivalent to high frequency dielectric permittivity. As the impurity content grows, the real part of the dielectric constant becomes negative, and its imaginary part is no longer negligible.

Fig. 3. Real (solid line, ε1) and imaginary (dotted line, ε2) part of dielectric permittivity of n-type silicon with different impurity concentration at 1 THz(**).

Due to this, THz losses in silicon grow. Loss tangent can be calculated using the following formula: tanδ=1/(ω*εv*ε0*R), where ω - circular frequency, εv - dielectric constant of vacuum (8.85*10-12 F/m), ε0 - dielectric constant of silicon (11.67), and R - specific resistance. For example, loss tangent of HRFZ-Si with resistivity 10 kOhm*cm at 1 THz is 1.54*10-5.

For more information about general properties of silicon, as well as transmission spectra in near and middle IR regions, refer to the chapter Silicon.

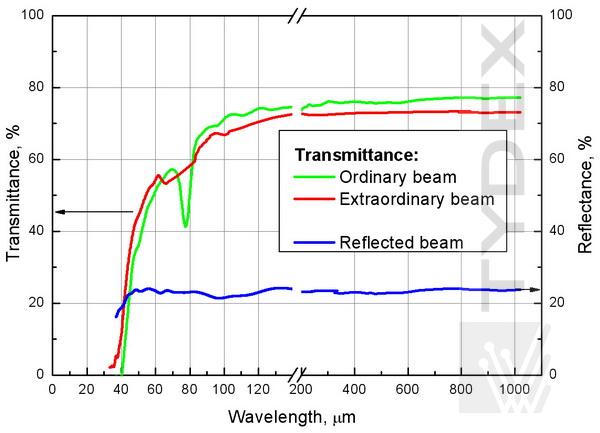

One of the best materials for wavelengths above 50 µm is a z-cut crystal quartz. The z-cut crystal quartz windows demonstrate the following important properties:

- They’re transparent in the visible range, making it easy to adjust the optical system by means of HeNe laser;

- They do not affect linear polarization of the beam;

- They can be cooled below the λ-point of liquid helium.

Fig. 4. Transmittance of 1 mm-thick crystal quartz sample.

Due to relatively high dispersion (see table below) crystal quartz lenses will have different focal lengths in visible and THz ranges. This should be taken into account if such lenses are used to adjust optical systems.

|

Crystal quartz is birefringent. This must be considered if the polarization of light is critical for your application. We use x-cut material for λ/2 and λ/4 waveplates operating at THz frequencies.

For more information about general properties of crystal quartz, as well as transmission spectra in UV and visible regions, refer to the chapter Synthetic Crystal Quartz.

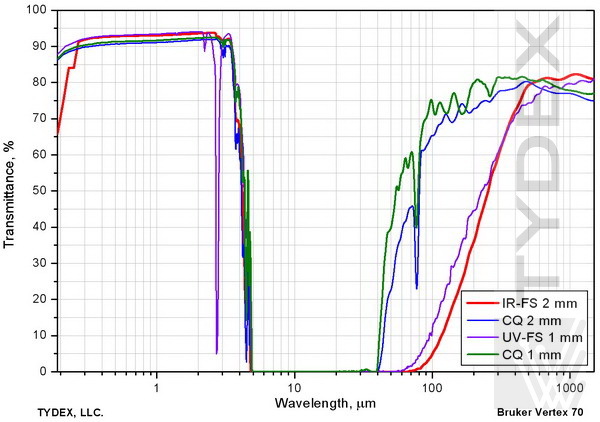

Thin fused silica elements also transmit long-wavelength radiation. Above 500-700 μm the transmittance is the same as that of the crystalline material. In millimeter-wave applications, thin fused silica parts can be used to save costs.

Fig. 5. Transmittance of crystal quartz windows KI and KU-1 of various thicknesses.

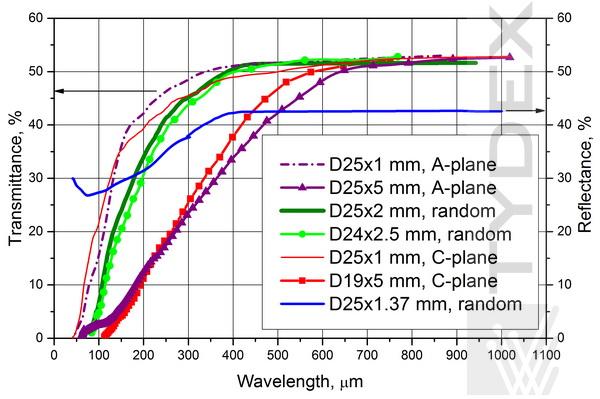

Like crystal quartz, sapphire is transparent both in submillimeter and visible ranges. As it is clear from the spectra below, sapphire transmittance does not depend on its crystal orientation. For measured samples 1 to 55 mm thick, transmittance below 600 μm is highly dependent on sample thickness. For thinner samples, transmittance approaches saturation at shorter wavelengths. Similar to high-resistivity silicon, sapphire with its comparable refractive index can be used for hyper hemispheric lenses for THz detectors and generators based on photoconductive antennas.

For more information about general properties of sapphire, as well as transmission spectra in UV and visible regions, refer to the chapter Sapphire optics on our website.

Fig. 6. Transmittance of sapphire samples of various different thicknesses and crystal orientations

2. Polymers

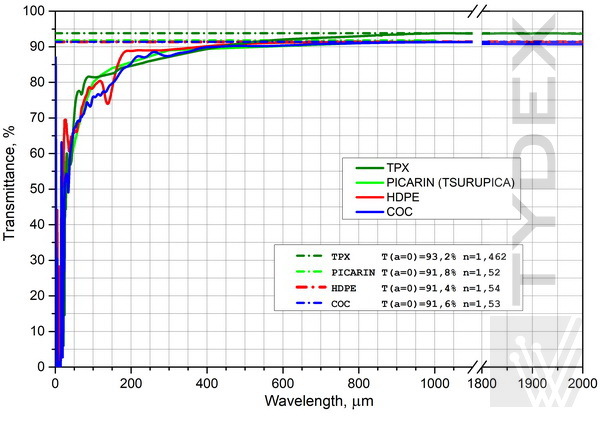

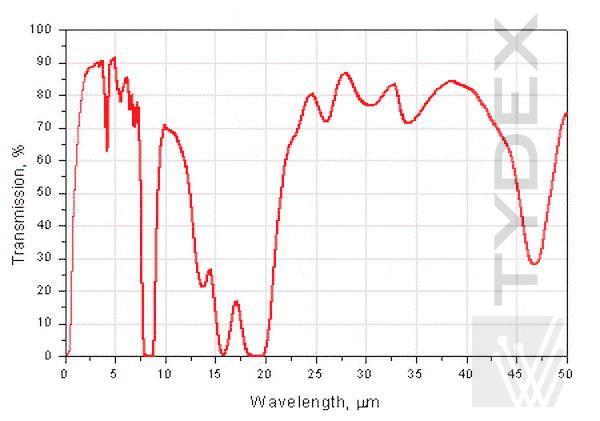

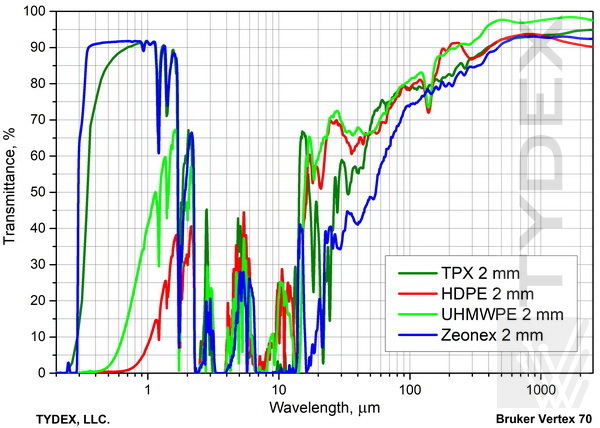

Among wide variety of polymers, there are some of excellent terahertz transparency with relatively low reflectivity. The best materials in this regard include polymethylpentene (TPX), Picarin (Tsurupica), cyclic olefin polymer (Zeonex), cyclic olefin copolymer (COC), polyethylene (PE), and polytetrafluoroethylene (PTFE or Teflon). At 200 μm and above, transmittance of these polymers is over 80% and independent of wavenelgth. Below that, characteristic absorption bands appear due to natural oscillations. Scattering on various inhomogeneities also increases. TPX, Tsurupica, Zeonex and COC are transparent in visible range.

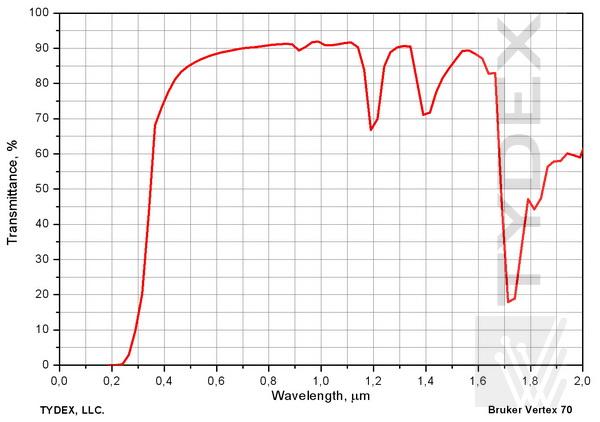

TPX is the lightest of all polymers. It is transparent in UV and far IR, as well as visible range, allowing optical systems to be adjusted using a HeNe laser beam. Its refractive index is ~1.46 with almost no dispersion.

|

Optical losses in the material are very low up to millimeter wavelengths. TPX has excellent heat resistance and is highly resistant to most commercially available chemicals, both organic and inorganic.

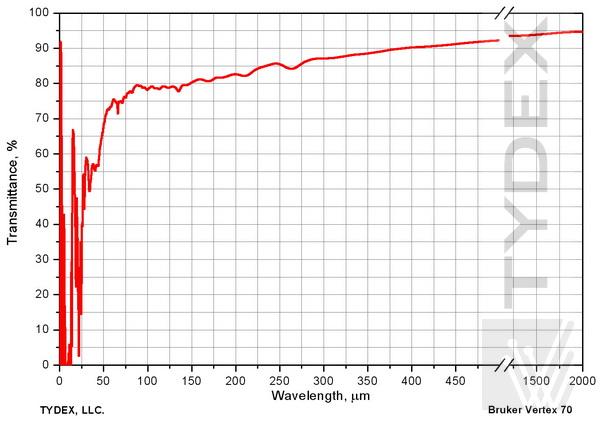

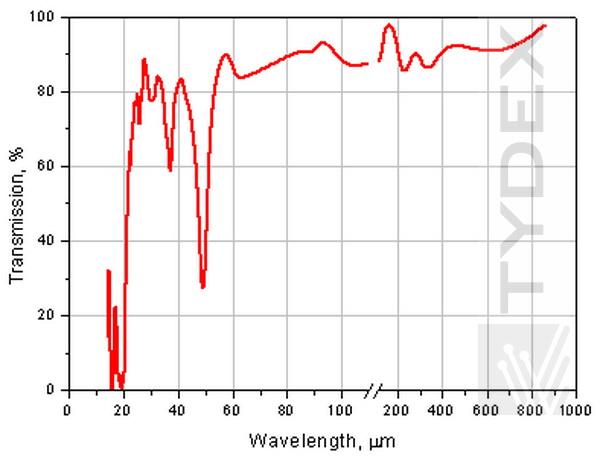

Fig. 7. Transmittance of a 2 mm thick TPX sample. THz range.

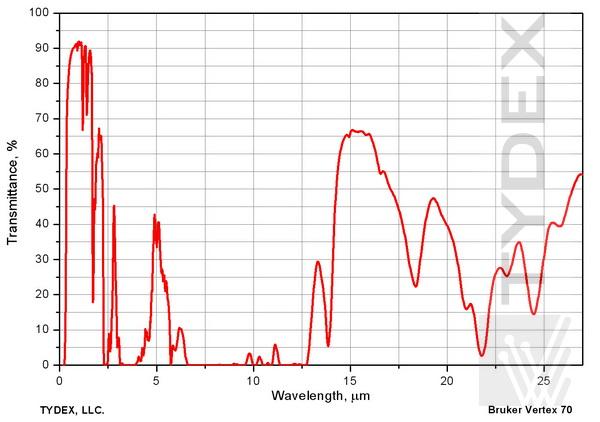

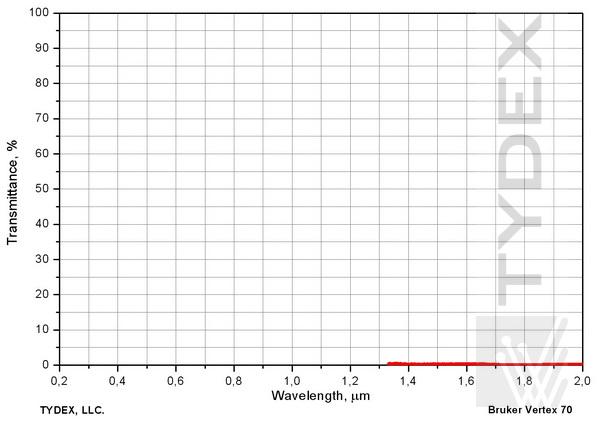

Fig. 8. Transmittance of a 2 mm thick TPX sample. NIR and MIR regions.

Fig. 9. Transmittance of a 2 mm thick TPX sample. UV, visual & NIR ranges.

Typical TPX properties:

| Density, g/cm3 | 0.83 |

| Tensile strength | 4100 psi ~28.3 MPa |

| Tensile modulus | 280000 psi ~1930.5 MPa |

| Tensile elongation at break, % | 10 |

| Flexural strength | 6100 psi 42.1 MPa |

| Flexural modulus | 210000 psi 1447.8 MPa |

| Heat deflection temperature, °C | 100 |

| Melting temperature, °F/°C | 464/240 |

| Water absorption (ASTM-D 1228), % | <0.01 |

| Moisture permeability (thk 25 µm, 40C, 90%RH), g/m2*24h | 110 |

| Oxygen permeability (thk 100 µm), cm3/m2*d*MPa | 120000 |

| Modulus of rupture | 6100 psi |

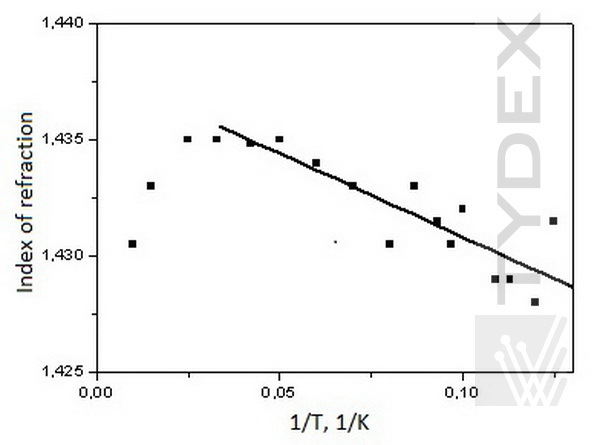

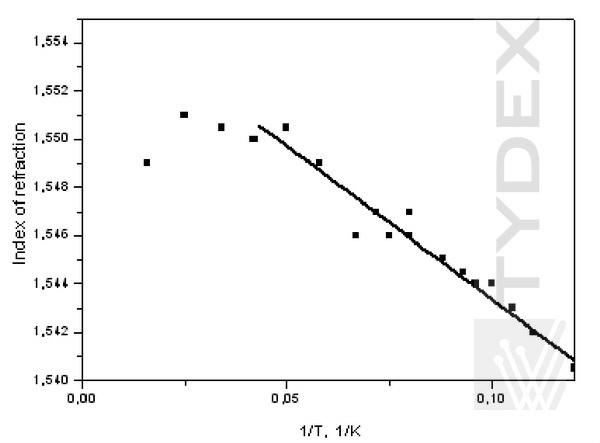

One more specific use of TPX should be mentioned. It can be used as an output window in CO2-pumped molecular gas lasers due to its transparency throughout the entire THz range, and absolute suppression of pumping radiation around 10 μm. TPX windows can also be used in cryostatic applications as “cold” windows. TPX transmittance in THz region is virtually temperature independent. Temperature coefficient of the refractive index is 3.0*10-4 K-1 in the temperature range 8-120 K.

Fig. 10. Temperature dependence of refractive index.(***)

Excellent optical properties of the TPX make it a good substitution for Picarin (Tsurupica) lenses.

Fig. 11. Transmittance of 2 mm thick samples of TPX, PICARIN, HDPE and COC.

In vacuum applications TPX windows can be used down to 10-9 mm Hg.

Besides that, we provide a cyclo olefin polymer ZEONEX® to use in an ultra-high vacuum environment (10-9 – 10-11 mm Hg). It is characterized by excellent mechanical properties, good chemical stability and very low outgassing in a vacuum. Key characteristics of this material are given below.

Typical ZEONEX properties:

| Density (ASTM D792) | 1.01 g/cm3 |

| Tensile modulus (ISO527-2) | 363000 psi |

| Elongation at failure (ISO527-2) | 10 % |

| Bend strength (ISO178) | 15100 psi |

| Bending modulus (ISO178) | 363000 psi |

| Hardness (JIS K5401) | F |

| Heat deflection temperature (JIS D648) | 122°C |

| Glass transition point (JIS K7121) | 139°C |

| Thermal expansion coefficient (ASTM E831) | 6*10-5 cm/cm°C |

| Water absorption (ASTM D570) | <0.01% |

| Refractive index (ASTM D542) | 1.531 |

| Modulus of rupture | 15100 psi |

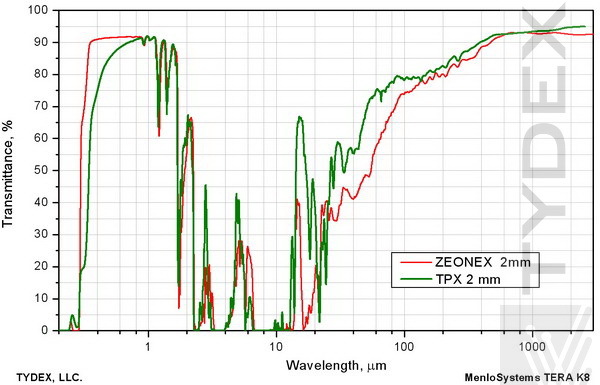

Similar to TPX, due to visible transparency and absence of refractive index dispersion, the ZEONEX terahertz optical systems can be adjusted using a HeNe laser beam.

It should be noted that ZEONEX has better transmittance in visible region than TPX.

Fig. 12. Transmission of 2 mm-thick ZEONEX and TPX windows.

Better mechanical properties of ZEONEX as compared to TPX make it possible to manufacture prisms of this plastic.

2.3 Polyethylene (PE)

Polyethylene is widely used in different applications due its ready availability and low cost.

We use high density polyethylene (HDPE) for windows of Golay cells.

Typical HDPE properties:

| Density | 0.96 g/cm3 |

| Tensile modulus (ISO 527) | 1100 MPa |

| Shore D hardness (ISO 868) | 64 |

| Tensile yield point (ISO 527-1) | 43 МРа |

| Tensile elongation (ISO 527-1) | 9% |

| Linear thermal expansion coefficient (ISO 11359-1;2), 10-5K-1 |

18 |

| Operating temperature range (long-term) | -50 - +80 °C |

| Operating temperature range (short-term) | +90 °C |

Fig. 13. Transmittance of a 2 mm thick HDPE sample. THz range.

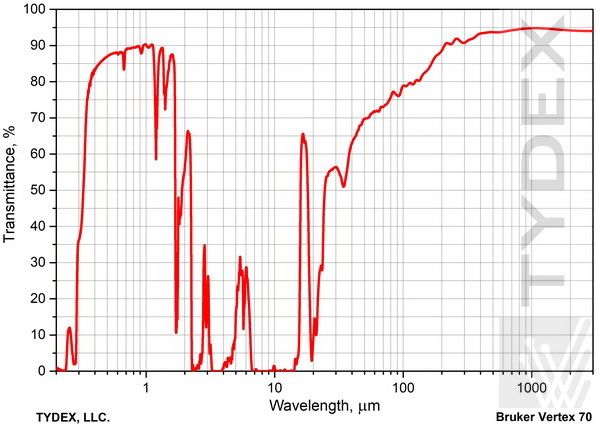

Fig. 14. Transmittance of a 2 mm thick HDPE sample. NIR and MIR regions.

Fig. 15. Transmittance of a 2 mm thick HDPE sample. VIS & NIR ranges.

Unfortunately, HDPE has very low transmittance in visible range, thus it can't be used for adjustment of optical systems.

It should be noted that HDPE transmittance in the THz range is virtually temperature-independent, making it possible to use it both at liquid helium and liquid nitrogen temperatures. Temperature coefficient of the refractive index is 6.2*10-4 K-1 in the temperature range 8-120 K.

In engineering applications, ultra-high molecular weight polyethylene is preferred because of its higher durability and lower friction coefficient as compared to HPDE.

Of all the grades of polyethylene, ultra-high molecular weight PE 1000 (UHMWPE) has the most balanced properties. This material combines excellent durability with great impact strength, even at low temperatures. It also has a good combination of rigidity and damping capacity and can be easily welded. It has low water absorption, resistant to most chemicals and can be machined easily.

UHMWPE is a great alternative for PTFE 4 at operating temperatures not exceeding 60-70°C.

Typical UHMWPE properties:

| Density | 0.93 g/cm3 |

| Water absorption, % (ISO 62) | <0.01 |

| Tensile modulus (ISO 527) | 680 MPa |

| Shore D hardness (ISO 868) | 63 |

| Wear resistance (vs sand slurry) | 80 |

| Melting temperature | 135 °C |

| Linear thermal expansion coefficient (DIN 53752), 10-5K-1 |

150-230 |

| Operating temperature range (long-term) | -250 - +80 °C |

| Operating temperature range (short-term) | 130 °C |

| Softening temperature (ISO 306) | 79 °C |

Fig. 17. Transmittance of a 2 mm thick UHMWPE sample.

2.4 Polytetrafluoroethylene (PTFE, Teflon, in Russian - Ftoroplast)

PTFE is a white, hard and heavy plastic. Its density is around 2.2 g/cm3. PTFE melts at 327°C and retains its useful properties in a wide temperature range between -73°C and 204°C. Refractive index is ~1.43 in a wide wavelength range.

Fig. 18. Transmittance of a 0.1 mm thick PTFE film. THz range.

Fig. 19. Transmittance of a 0.1 mm thick PTFE film. NIR and MIR regions.

Due to good transmissionin the range 1-7 µm PTFE films are used for manufacturing of IR polarizers. Such polarizers are cheaper to manufacture than crystalline ones. This is a significant advantage for mass production of IR sensors using polarized light.

Typical PTFE properties:

|

2.5 Cyclic Olefin Copolymer (COC)

Main advantages of the Cyclic Olefin Copolymer (COC) are its high operating temperature, excellent transmittance, low birefringence and low water absorption.

Characteristics of the material we use for aspherical THz f-theta lenses are given below.

Typical COC properties:

|

Fig. 20. Transmittance of a 2 mm thick COC window.

Summary

As you can see, the selected organic materials, including TPX, ZEONEX, COC, PE, and PTFE, have uniform transmittance about 80-90% starting from ~200 µm and up to 1000-2000 µm. Naturally, they provide excellent transmittance at larger wavelengths as well.

Comparison of transmittance spectra of polymer windows of the same thickness allow to select the most appropriate material for a specific application.

Fig. 21. Transmittance of 2 mm thick TPX, ZEONEX, HDPE and UHMWPE windows.

Crystalline materials such as silicon, quartz and sapphire demonstrate lower transmittance in THz region due to reflective losses. Specifically, it’s 50-54% for silicon starting from 50 μm, >70% for quartz from ~120 μm, >50% for sapphire from ~350 μm given 1-2 mm samples.

Please note we do not supply raw or semi-finished polymer and crystalline materials. We only deal in finished items. For the whole range of devices and components we supply for THz applications, please refer to the following sections of our site: THz Assemblies, THz Devices, THz Polarizers, THz Optics.

For price quotation and delivery please fill in our Request Form.

_________________

(*) data are given by X.- C. Zhang and Jian Chen from Rensselaer Polytechnic Institute, USA.

(**) X.- C. Zhang, J. Xu, Introduction to THz Wave Photonics, Springer Science+Business Media, LLC 2010 (p. 73).

(***) data are given by J. Steven Dodge and Graham Lea from Simon Fraser University, Canada.

Optics is ready to be shipped!

Optics Stock

Shipment/ Payment/ Warranty ...