Astro-Optics

| Download Astro-optics Datasheet (PDF, 417 KB) |

| Download SL LAB, INC brochure about Manufacturing Space and Ground telescope (PDF, 4 MB) |

Development of optical components for astronomical applications has always been one of Tydex's main lines of business. Since its establishment, the Tydex Company has gained considerable experience in the production of high-precision mirrors, optical lenses, and various unique optical components. As of August 2007, the company has sold more than 360 various astronomical systems such as Cassegrain, Ritchey–Chretien, and others with an aperture of up to diameter 1260 mm. In addition to complete lens/mirror sets, Tydex sold a great many plane, diagonal, spherical, parabolic, and hyperbolic mirrors as well as lens and lens sets for astro-correctors of different specifications, from standard to unique. Today, Tydex's mirrors serve as components of telescopes and research equipment in Germany, France, Italy, Japan, the USA, China, Chile, Taiwan, Korea, and many other countries.

Nowadays, Tydex produces and delivers single high-precision mirrors and complete mirror/lens sets for professional astronomical systems. The company offers spherical, parabolic, hyperbolic, and plane mirrors with reflecting surfaces of various shapes, optical lenses for astro-correctors, and various nonstandard components with different specifications. The range of astronomical systems equipped with Tydex's optical components includes Newton, Cassegrain, Ritchey–Chretien, Maksutov, and Mersen telescopes, astrophotography systems, etc.

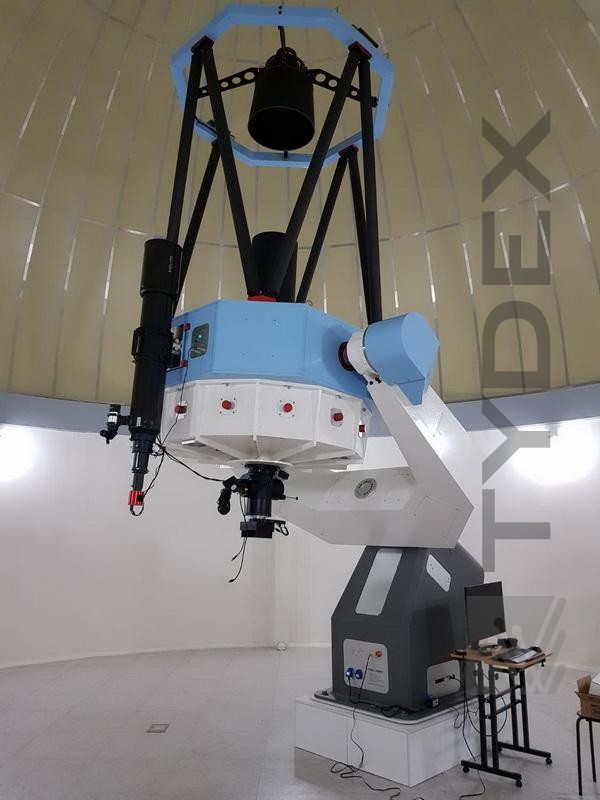

Tydex supplied a main mirror (concave hyperbolic mirror with Dout=1230mm), a secondary mirror (convex hyperbolic mirror with Dout=400mm) and a 2-lenses optical corrector for telescope Astera1200 by SLLAB INC.

Location: Gwangju National Science Museum, Gwangju City, South Korea.

Description of standard astronomical systems:

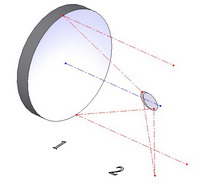

| Newton telescope | |

|

1 – primary element, 2 – secondary element, |

| The Newton telescope is classed among amateur astronomical systems. The main disadvantages of this design are long tube (as compared with other designs) and inconvenient eyepiece at its upper end. This is why this design is not employed to make large instruments. However, owing to easy tuning and low price, this system still attracts the interest of some customers. | |

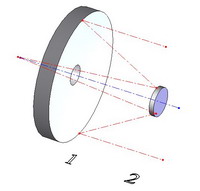

| Cassegrain telescope | |

|

1 – primary element, 2 – secondary element, |

| The Cassegrain telescope appears to be the most popular astronomical system used by both professionals and amateurs. It provides good seeing yet a narrow field of view. In contrast to the Newton telescope, the secondary element in the Cassegrain design is a convex hyperbolic (rather than plane diagonal) mirror intended to focus light into an image just outside the central hole of the primary mirror. This allows making the tube shorter by 50%, which in turn reduces the cost of the telescope and its dome. | |

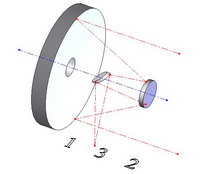

| Cassegrain–Nasmyth telescope | |

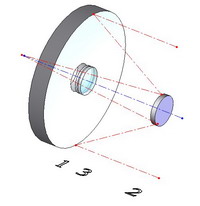

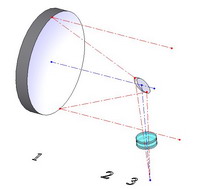

|

1 – primary element, 2 – secondary element, 3 – tertiary element, |

| Incorporating all the advantages of the classic Cassegrain, the Cassegrain–Nasmyth design has a tertiary element - a plane diagonal mirror - that allows the image to be formed on a side plane. This feature makes the instrument more universal, but the presence of only one reflecting surface reduces the reflecting power of the system as a whole. | |

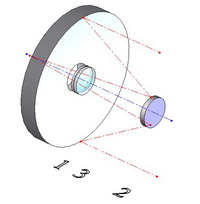

| Hypergraph | |

|

1 – primary element, 2 – secondary element, 3 – tertiary element, |

| Astronomers' efforts to improve the classic Cassegrain design resulted in the Hypergraph . Its distinguishing feature is a tertiaryelement—an optical corrector—which improves image quality. Currently, hypergraphs are most frequently used as professional instruments because they require accurate design and precise alignment. | |

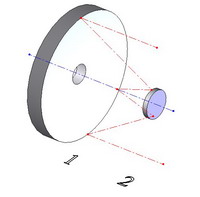

| Ritchey–Chrétien telescope | |

|

1 – primary element, 2 – secondary element, 3 – tertiary element, |

| Like the Cassegrain, the Ritchey–Chrétien telescope is deservedly favored by professionals. What distinguishes it from other systems is that each of its two hyperbolic mirrors cannot form an image independently. Nevertheless, the system performs excellently but needs an optical corrector to eliminate astigmatism and, thus, to increase the field of view. | |

| Schwarzschild telescope | |

|

1 – primary element, 2 – secondary element, |

| The Schwarzschild telescope is similar in design to the Ritchey–Chrétien one with the only difference that the former does not have an optical corrector. This system produces a wide field of view without astigmatism but requires that the spacing between the mirrors be twice as great as the focal distance. Since the image is formed inside the system, between the mirrors, the Schwarzschild design is inconvenient to use and, thus, is rarely implemented. Nevertheless, this design was used to create a number of special instruments. | |

| Maksutov telescope | |

|

1 – primary element, 2 – secondary element, |

| The Maksutov telescope is distinguished by having a meniscus lens with a mirrored spot intended to correct the spherical aberration of the primary mirror. This design is behind many amateur telescopes. It is advantageous by combining a compact tube and a wide filed of view, whereas its disadvantage is a low focal ratio. The difficulties associated with the making of large-diameter corrector lens restrict the use of this design for the creation of big professional instruments. There are modifications of this system (Maksutov–Newton, Maksutov–Cassegrain) that differ by the direction of the output beam. | |

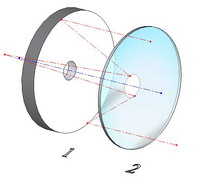

| Astrophotography system | |

|

1 – primary element, 2 – secondary element, 3 – tertiary element, |

| Astrophotography systems, as the name suggests, are mainly used to take pictures of celestial objects. Such systems, consisting of several independently manufactured components, are relatively simple in design and popular among amateurs. A mandatory component is a special corrector lens intended to form a usable imaging field of view and to correct aberrations. There are different optical designs of astrophotography systems. One is shown in the figure. Another frequently used design does not have diagonal mirror, and its corrector is on the optical axis. | |

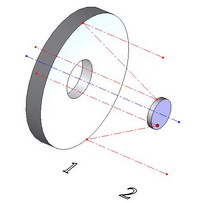

| Mersenne telescope | |

|

1 – primary element, 2 – secondary element, |

| The Mersenne telescope is a reflector of nonstandard design. It forms the image at infinity. This design is usually used in various lidar systems intended, for example, to monitor atmospheric turbulence. | |

General specifications for astronomic mirrors and systems

Materials:

Astronomical mirrors are usually made of Zerodur (Schott Glass Technologies, Germany) or its Russian prototype Sitall CO-115M (Astrositall), fused silica, Pyrex (Corning Incorporated, USA) or its Russian prototypes LK5 and LK7 glass. Materials are chosen so as to comply with the specifications, operating conditions, and purpose of optical systems.

Surface accuracy:

The experience of our opticians and the available instruments and special equipment allow our company to produce optics with a wavefront accuracy of L/10 at 633 nm or, what is the same, a surface accuracy of L/20.

Surface quality:

All our products fully comply with the internationally recognized MIL-0-13830A standard. The surface quality of the mirrors produced by the company depends on their dimensions:

• 60/40 scratch/dig for linear dimensions up to 400 mm;

• 80/50 scratch/dig for linear dimensions up to 800 mm;

• 120/80 scratch/dig for linear dimensions more than 800 mm.

Coating:

Protected aluminum is our most popular coating for astronomic mirrors. Upon the Customer's request, we can apply coatings of other types, if the Company's capabilities allow.

Available dimensions and standard specifications:

Spherical mirrors

• Diameters: from 200 mm to 1300 mm;

• Wavefront accuracy: up to L/8 at 633 nm (or surface accuracy: up to L/16);

• Standard numerical apertures: F/3–F/10.

Parabolic and hyperbolic mirrors

• Diameters: from 200 mm to 1300 mm;

• Wavefront accuracy: L/8 at 633 nm (or surface accuracy: L/16);

• Standard numerical apertures: F/3–F/10.

Plane elliptic diagonal mirrors

• Minor axis dimension: from 30 mm to 250 mm;

• Wavefront accuracy: L/8 at 633 nm (or surface accuracy: L/16).

Standard astronomical systems

• Wavefront accuracy (of a ready-assembled system): L/8 at 633 nm (or surface accuracy: L/16);

• Diameters of primary mirrors: from 400 mm to 1300 mm;

• Standard numerical apertures of primary mirrors: F/3–F/10;

• Standard numerical apertures of systems: F/7–F/20.

Quality assurance

Each astronomical mirror/system is subject to exhaustive testing. The results of testing are documented in a test certificate. The interferograms are subject to numerical analysis. The Customer is provided with all test results and original interferograms (including negatives).

The above types of mirrors and their specifications are standard and do not exhaust all the range of products that can be offered. For more about the Company's production potentialities, prices, and delivery times, please contact us.

For price quotation and delivery please fill in our request form.

Optics is ready to be shipped!

Optics Stock

Shipment/ Payment/ Warranty ...